Automatic or manual feeding

Solid-liquid separation is achieved under vacuum or pressurized conditions.

Spray balls are installed inside the container, which can evenly spray the cleaning liquid into the container. After adding a certain amount of cleaning liquid, the agitator will rotate clockwise wash the material. After washing, the material can undergo repeated processes such as pressure filtration and washing, and the specific number of times depends on the process.

Inject heat medium into the cylinder jacket, cone jacket, and agitator to continuously heat the filter cake inside the tank. At this time, the agitator rotates clockwise at low speed, causing multi-dimensional movement of the material inside the tank. Through all-round irregular reciprocating movement, efficient heat exchange of materials can be achieved, while a hot gas source can be introduced into the tank to improve drying efficiency.

After drying, the material inside the container can be discharged from the bottom outlet by opening the bottom discharge valve.

Cylinderical and conical structure design

Large filtration area | Large equipment capacity | Split structure

Special discharge valve

Special discharge valves are used to avoid incomplete solid-liquid separation.

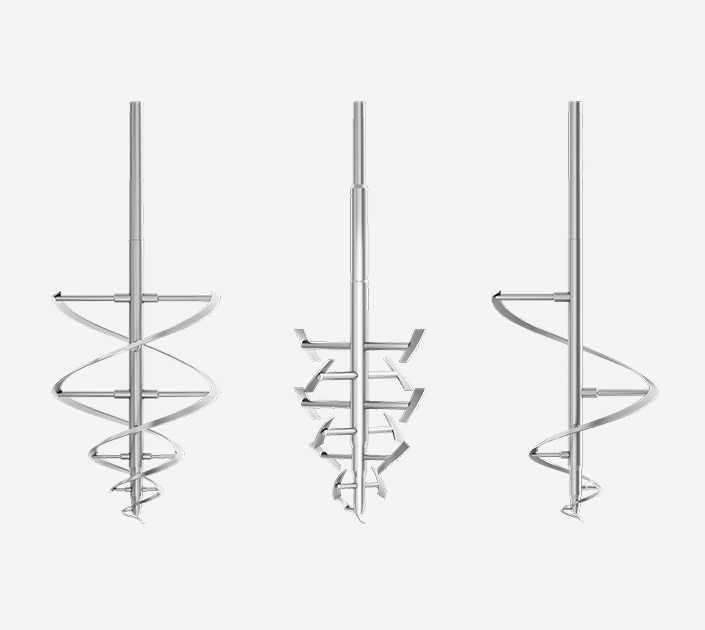

Agitator Design

Various agitators can be provided for customers to choose from.

The agitator can be heated to accelerate drying efficiency.

01

02

03

04

05

06

07

08

The control system is composed of an industrial grade touch tablet computer (IPC) and a programmable logic controller (PLC), which can easily achieve full automatic control. The screen display is friendly, and the monitoring interface, operation interface, formula interface, and other interfaces are distributed reasonably. The enterprise simplifies the process of batch production during use. Fully functional user permission management, access permission settings, etc., ensuring the security of user use. Key records such as electronic signatures and audit trails, formula management, batch reports, data backup, and other functions are provided to meet the integrity of data saved by enterprises during use.

According to the GAMP guidelines, in order to ensure that the computerized system meets the intended use and existing regulations, our company can independently conduct computer system verification to meet the verification needs of enterprises.

User permission management

Access permission settings

Electronic signatures

Audit trails

Formula management

Batch reports

Data backup

Online monitoring

| Model | Filter basket inner dia (mm) | Filtering Area(m²) | Total Volume(m³) | a(mm) | b(mm) | Motor Power(kw) | Net Weignt(T) |

|---|---|---|---|---|---|---|---|

| CFD550 | 550 | 0.4 | 0.135 | 750 | 1850 | Depending on the customer’s material conditions, options are available in the range of 3-55KW. | 0.7 |

| CFD700 | 700 | 0.7 | 0.32 | 1100 | 2500 | 1 | |

| CFD1000 | 1000 | 1.4 | 0.87 | 1280 | 2850 | 2.3 | |

| CFD1200 | 1200 | 2.1 | 1.5 | 1630 | 3500 | 2.7 | |

| CFD1400 | 1400 | 3 | 2.5 | 1850 | 4150 | 3.5 | |

| CFD1600 | 1600 | 3.8 | 3 | 1900 | 4200 | 4.3 | |

| CFD1800 | 1800 | 4.8 | 5 | 2300 | 4800 | 5.7 | |

| CFD2000 | 2000 | 6.1 | 6.2 | 2500 | 5800 | 8.4 | |

| CFD2200 | 2200 | 7.3 | 8.5 | 2700 | 6300 | 10 | |

| CFD2400 | 2400 | 8.8 | 10.8 | 3000 | 6800 | 13.6 | |

| CFD2600 | 2600 | 10.2 | 14 | 3200 | 7200 | 17 | |

| Note:It can be designed and manufactured according to the special requirements of users. | |||||||

Agitated Nutsche Filter Dryer For Pharmaceutical Industry ...

The chemical grade Agitated Nutsche Filter Dryer can be ...

The turnover type fitering and drying Machine developed and ...

Crystallization Agitated Nutsche Filter Dryer is suitable ...

Address : No. 558 Binhai 8th Road, Binhai Park, Economic and Technological Development Zone, Wenzhou, Zhejiang Province, China

Te : +86-0577-86906886

Fax : +86-0577-86906900

E-mail : marketing@china-yaguang.com

P.C. : 325025

Copyright © Zhejiang Yaguang Technology Co., Ltd. ALL Rights Reserveds