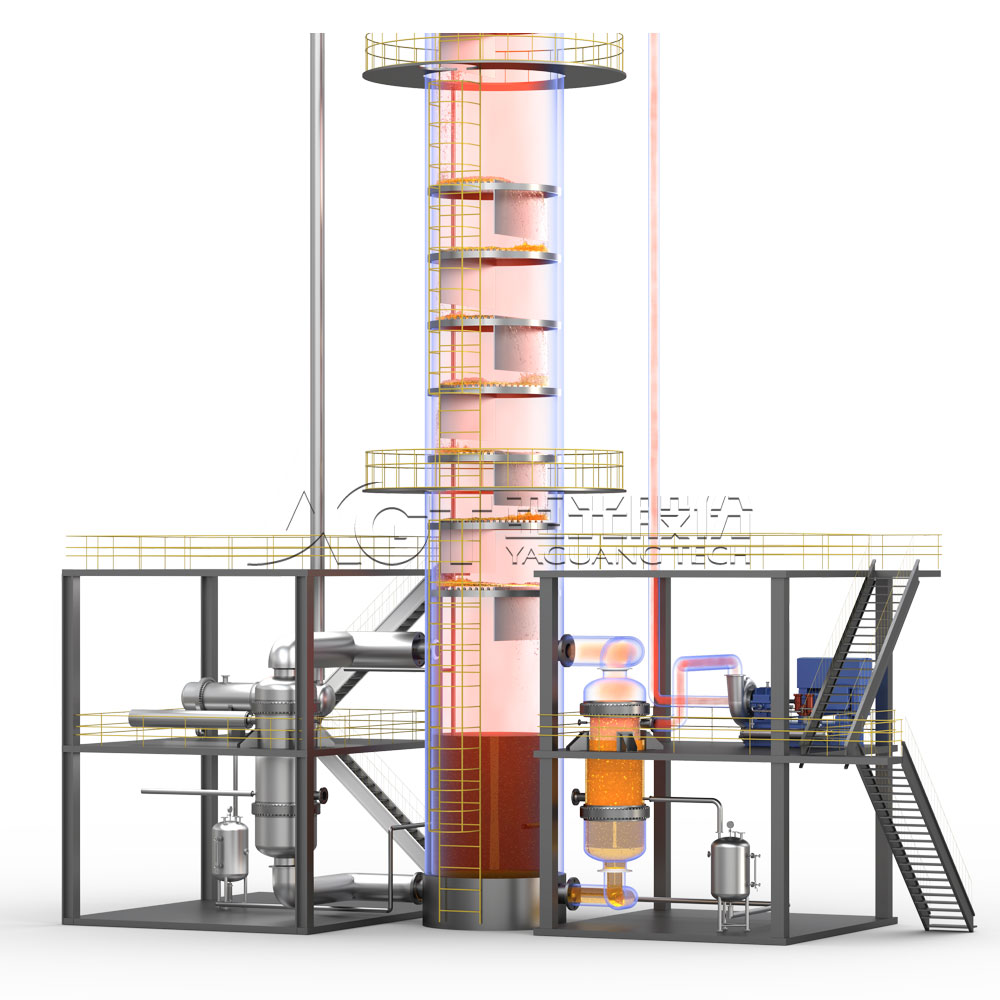

Heat pump distillation process

Continuous compression cycle of secondary steam as a heating source

Compressing the low-temperature gas at the outlet through the compressor without condensation, increase the temperature and pressure of the gas, increase the enthalpy value of the gas, and then use it as the heat source of the reboiler to heat the material, making full use of the latent heat of the gas and reducing the production of steam. consumption and circulating water to reduce operating costs.

Indirect steam compression type

Tower top steam compression type

Based on your existing heat pump distillation equipment and operating conditions,

we provide MVR heat pump energy-saving renovation solutions to maximize its energy-saving effect;

Customize different types and pressure ratios of steam compressors according to different

operating conditions and technical requirements in different fields and specific environments.

01

we are one of the few evaporator manufacturers in China that has mastered steam power equipment technology.

02

Leheng with independent research and development property rights in MVR core technology.

03

Compressors of different categories and models can be flexibly applied to different application scenarios

Over 30000 hours of operating life

Through high-strength materials, precise processing technology, and strict testing methods, we ensure that the service life of the impeller reaches 30,000 hours.

High strength titanium alloy TC4 carefully forged

The impeller material is forged from high-strength, wear-resistant, and highly corrosion-resistant titanium alloy material, and is precision milled through a five-axis linkage milling machine.

Excellent dynamic balance performance and high standard strength testing

It has passed double-sided dynamic balancing of no less than G1.0 level and an overspeed test of no less than 15% of the working speed to verify its strength.

Strict factory inspection

After each impeller is processed, it undergoes strict factory inspections such as non-destructive testing and three-dimensional testing, providing customers with products that meet quality requirements.

Energy consumption comparison between heat pump distillation and traditional distillation column

A. 2500m ³/ D Ammonia nitrogen wastewater treatment system heat pump renovation project

Renovate the existing deamination tower with a heat pump. The ammonia-containing vapor at the top of the tower enters the falling film evaporator to exchange heat with water. After the heat exchange, the vaporized low-temperature and low-pressure water vapor enters the compressor and becomes high-temperature and high-pressure gas after compression and enters the tower. The kettle coupled reboiler exchanges heat with the tower kettle wastewater to save industrial steam consumption.

| Table 1: Parameters of ammonia nitrogen wastewater to be treated | ||||

|---|---|---|---|---|

| No. | Item | Unit | Value | Remark |

| 1 | Amount of water | m³/d | 2500 | |

| 2 | pH | Dimensionless | 12~12.8 | |

| 3 | NH3 | g/L | 5~10 | Calculated by 6 |

| 4 | Na2SO4 | g/L | 100~150 | |

| 5 | Ni、Co、Mn | mg/L | 100~200 | Calculated by 100 |

| 6 | Temperature | ℃ | 20~60 | |

| 7 | Cl- | mg/L | <20 | |

| Table 2: Deamination tower top kettle outlet parameters | ||||

|---|---|---|---|---|

| Customer parameter requirements | Item | Unit | Value | Remark |

| Ammonia-containing steam at the top outlet of the tower | Flow | t/h | 12.56 | To evaporator |

| Component | Ammonia (20%), water | |||

| Temperature | ℃ | 95±5 | ||

| Pressure | kPa | 101 | ||

| High temperature water at the outlet of the tower kettle | Flow | t/h | 107 | Reboiler |

| Component | Water, sodium sulfate (100-150g/L), nickel cobalt manganese hydroxide (150-300mg/L), pH approximately 12 | |||

| Temperature | ℃ | 105±5 | ||

| Pressure | kPa | 101 | ||

|

Energy consumption comparison |

|||

|---|---|---|---|

| Comprehensive field application, the theoretical calculation through the large-scale chemical engineering simulation software Aspen Plus is as follows | |||

| Utility Conditions | Circulating water | 0.2 | Yuan/T |

| Electricity | 0.7 | kW.h | |

| Steam | 250 | Yuan/T | |

| Continuous operation for one year | Hour | 7920 | 330 days |

| Feeding 105m³/h ammonia-containing wastewater, operating cost comparison table | |||||

|---|---|---|---|---|---|

| Device | Utilities | traditional distillation | Heat pump distillation | ||

| Energy consumption | Yuan/H | Energy consumption | Yuan/H | ||

| Reboiler | Steam T/H | 9 t/h | 2250 | 4 t/h | 1000 |

| Condenser | Circulating water T/H | 904 t/h | 180.8 | 600 t/h | 120 |

| Pump | Motor KW | 20 kw/h | 14 | 90 t/h | 63 |

| Compressor | Motor KW | 0 kw/h | 0 | 670 t/h | 469 |

| Total/yuan | 2445 | 1652 | |||

| Every 1 ton of wastewater treated Total/yuan | 23.3 | 15.7 | |||

| One year operating cost/10000 yuan | 1936 | 1308 | |||

| Annual cost savings/10000 yuan | 628 | ||||

| From the comparison in the above table, it can be seen that heat pump distillation saves operating costs of 6.28 million per year. The operating costs are calculated based on the parameters in Table 1 and Table 2 above. Changes in actual operating data will affect the operating costs. | |||||

Higee Rotating Zigzag Bed (RZB) is a new and efficient ...

Small size | Easy installation | Easy maintenance ...

Address : No. 558 Binhai 8th Road, Binhai Park, Economic and Technological Development Zone, Wenzhou, Zhejiang Province, China

Te : +86-0577-86906886

Fax : +86-0577-86906900

E-mail : marketing@china-yaguang.com

P.C. : 325025

Copyright © Zhejiang Yaguang Technology Co., Ltd. ALL Rights Reserveds