Separation of components with similar boiling points; Large consumption and high price of steam and circulating water; Widely used in the recovery of organic solvents such as methanol, ethanol, isopropanol, acetone, acetonitrile, tetrahydrofuran, dichloromethane, ethyl acetate, toluene, and the separation and purification of products,

Heat pump distillation process

Continuous compression cycle of secondary steam as a heating source

the low temperature gas at the top of the tower through the compressor without condensation, increase the temperature and pressure of the gas, increase the enthalpy value of the gas, and then serve as a heat source for the reboiler to heat the material, fully utilize the latent heat of the gas, reduce the amount of raw steam and circulating water, Reduce operating costs.

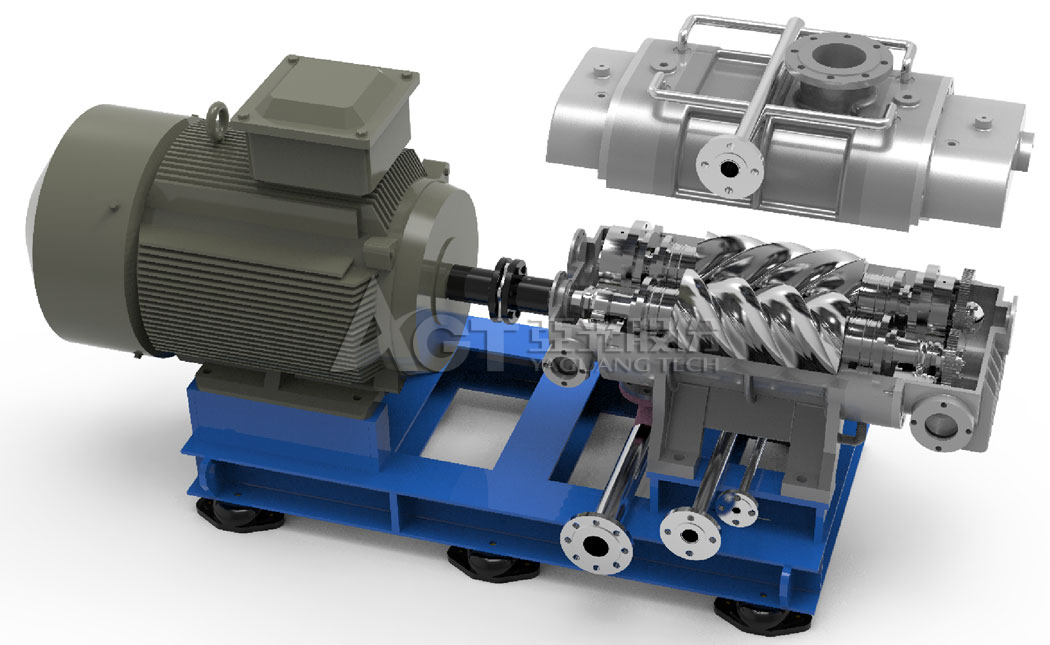

Supporting compressor:Rotary Screw Steam Compressor

Specially developed by Leheng, a subsidiary of Yaguang technology, to fill the distillation project with low flow rate and high pressure ratio

01

Small size, light weight, and easy maintenance

02

The introduction of specialized milling machines, especially grinding machines, for screw rotors has improved the machining accuracy and efficiency of these key components, effectively improving the performance of screw compressors.

03

The compressor adopts a modular design as a whole to facilitate disassembly and installation.

Customized design

Design the heat pump distillation system according to customer needs;

Customize different types and pressure ratios of steam compressors according to different operating conditions and technical requirements in different fields and specific environments.

Skip mounted design

Flexible use · Plug and Play

The Efficient Rotating Distillation Bed system developed by Yaguang Technology adopts a complete set of prefabricated skip mounted design, and the production and assembly of the equipment are completed in the factory. The on-site installation workload is minimal, and only joint pipelines and external electrical connections need to be completed. The equipment is compact and occupies less space than traditional installation methods, making it easy to install, transport, migrate, and maintain.

Experimental machines

Provide experimental machines according to customer requirements,

and connect the system with water and electricity to conduct experiments.

Experimental machine parameters

Distillation Bed model :XZLC-750-4C

Compressor:90KW screw compressor

Output:500L/h

Dimensions:7000×3200×3200 mm

Weight:12000kg

Higee Rotating Zigzag Bed (RZB) is a new and efficient ...

Separation of components with similar boiling points; Large ...

Address : No. 558 Binhai 8th Road, Binhai Park, Economic and Technological Development Zone, Wenzhou, Zhejiang Province, China

Te : +86-0577-86906886

Fax : +86-0577-86906900

E-mail : marketing@china-yaguang.com

P.C. : 325025

Copyright © Zhejiang Yaguang Technology Co., Ltd. ALL Rights Reserveds